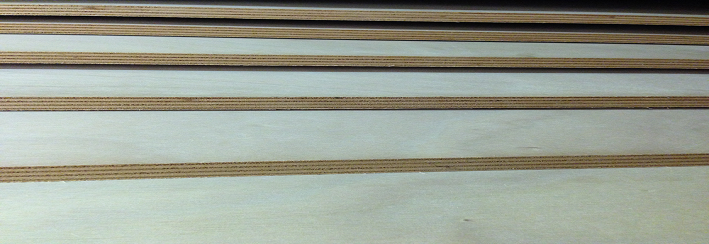

Marine plywood was developed for ship/boat building and has a very high performance under severe exposure conditions. It is also commonly used in construction applications where high performance is required or where the cost of replacement or consequences of failure warrant the additional cost. The glue used in Marine Plywood is the same as used in exterior grade plywoods (WBP = Weather and Boil Proof )). Its the quality of the veneers and the durability of the species of timber used in the veneers that make Marine Plywood better than ordinary exterior grade plywood.

Applications

The range of product applications for Marine Plywood Includes:

Marine Plywood was developed for ship/boat building and offers very high performance under severe exposure conditions

In extreme applications, such as boat hulls, we would recommend you select a kite-marked or lloyds approved hardwood.

Structural Characteristics

Manufactured in the Far East from moderately durable species to BS 1088·2003 'Plywood for Marine Craft' standards. The primary difference between FE marine and FE exterior grade is the quality of the core. Marine plywood has far fewer and smaller core gaps. This is especially important where there is potential for the ingress of moisture, which can collect in the voids. It is a product which is commonly specified in applications where performance is a critical issue

Sizes Available & Thickness

|

1220 x 2500 (Light weight) |

4mm |

|

1220 x 2500 (Light weight) |

6mm |

|

1220 x 2500 (Light weight) |

9mm |

|

1220 x 2500 (Light weight) |

12mm |

|

1220 x 2500 (Light weight) |

18mm |

|

1220 x 2500 (Light weight) |

25mm |

|

1220 X 2440 (Far Eastern) |

12mm |

|

1220 X 2440 (Far Eastern) |

18mm |

|

1220 X 2440 (Far Eastern) |

24mm |